Cookie files

This site uses cookies. Using this website you agree to the use of cookies in accordance with the current browser settings. Read more.

News

News from the life of the company

05.08.2025

Expansion allowing for optimal flow of goods and increased work ergonomics

As part of its development strategy, Płoszczyca Sp. z o.o. has expanded its infrastructure with a finished goods warehouse and a raw materials warehouse. This is one of the elements strengthening the logistics base and increasing the efficiency of internal processes.

The investment allows for the optimization of the flow of both raw materials and finished products, which contributes to greater flexibility in production planning. The larger storage space allows for more efficient work organization, faster order processing, and more effective inventory management, as well as streamlining the receipt and delivery of raw materials. As part of the new storage space, an area has been set aside for the preparation of raw materials for further processing, including guillotine cutting, saw cutting, preliminary processing of flat bars, etc.

The implementation of such a change allows for the optimization of operation times, as transport between individual production stations is eliminated because the raw material is located in the same part of the production area.

The new section was designed in such a way as to enable adaptation to growing needs and allowed for further development of the Płoszczyca company.

11.10.2024

Our Path to Innovation

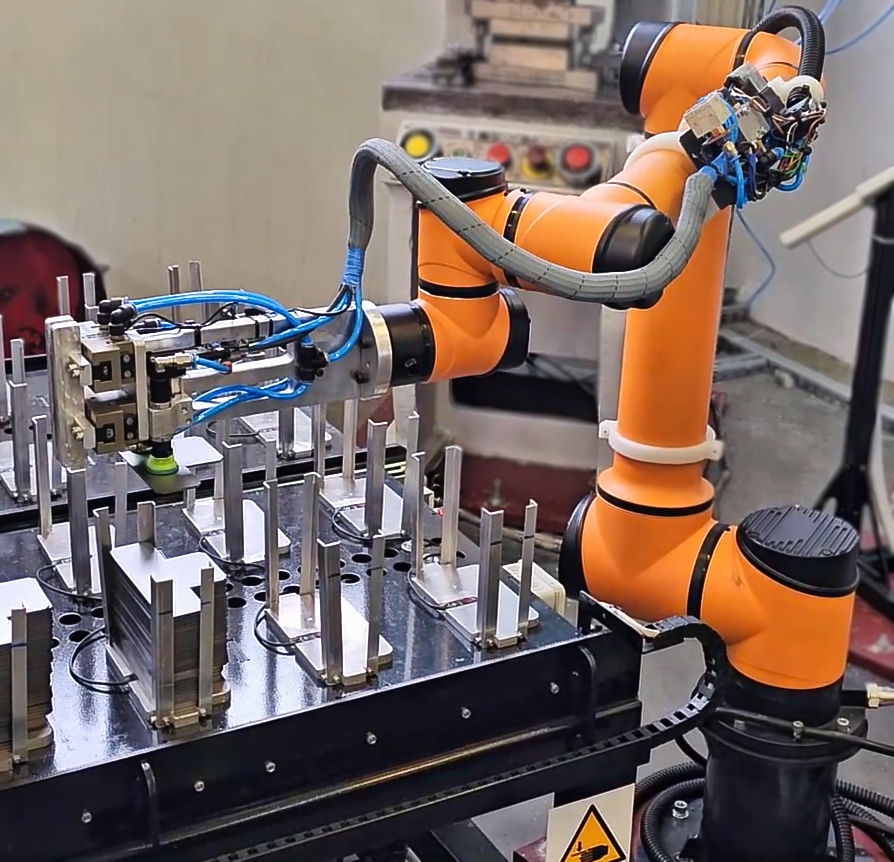

In today's rapidly changing technological world, companies must be flexible and open to innovation to meet market demands and customer expectations. Our company understands these needs very well, which is why we have implemented a cobot - a collaborative robot that aims to increase efficiency, but also opens up new opportunities in the fourth industrial revolution.

Thanks to it, we are able to automate many tasks that previously required human labor. In practice, this means that production becomes faster, more precise and less error-prone. The cobot also allows us to better customize production. In addition to the cobot, our production is also supported by a robotic station with a robotic arm capable of both measuring and sorting parts.

With flexible programs and quick reconfiguration capabilities, our production line can easily adapt to different tasks, which is crucial in today's diverse and demanding economy.